복잡하게도 연산 증폭기가 이렇게나 많은 이유

프로젝트에 적절한 또는 "최적인" 연산 증폭기(op amp)를 선택하는 일은 힘들고 까다로울 수 있습니다. 단일 공급업체만 검색하더라도 수십 개의 유사한 장치를 고려해야 하고, 더러는 새로운 장치가 출시되기도 합니다. 공급업체가 제공하는 선정 지침은 범주(예: 고속, 정밀도, 고전압)가 다양하여 도움이 될 수 있지만 이러한 범주도 서로 겹치거나 모호할 때가 많습니다.

그렇다면 왜 이렇게 많은 연산 증폭기가 있을까요? 냉소주의자는 "많으니까 많다"고 말할지 모르지만, 이는 진짜 이유가 아닙니다. 각각의 연산 증폭기 변형과 하위 변형마다 가격이 높아질 수 있으며 하나 이상의 설계, 제작, 테스트, 인증, 생산 계획, 주문 처리, 포장 등과 같은 요소의 변화가 필요하기 때문입니다.

이와 반대로 학계에서는 위의 질문에 "완벽한 연산 증폭기가 없기 때문"이라고 말할지도 모릅니다. 기술적으로는 맞는 말이지만 이 역시 진짜 이유가 아닙니다. 사실 무한한 대역폭, 잡음의 완전한 제거 및 기타 "불완전 요소"가 없는 이상적인 연산 증폭기는 필요한 수준 이상이기 때문에 이를 원하는 것은 아닐 수도 있습니다. 이러한 연산 증폭기를 응용 분야에 사용하려면 장치 자체의 제한된 대역폭에 의존하기보다는 외부 잡음이 연산 증폭기에 미치는 영향을 줄이기 위해 외부 필터를 추가해야 할 수 있습니다.

이렇게 많은 연산 증폭기가 존재하는 이유는 사실 두 가지 요인때문입니다. 첫 번째는 응용 분야가 매우 다양하다는 점입니다. 두 번째는 끝없는 트레이드 오프 성격의 엔지니어링 문제가 존재한다는 점입니다. 연산 증폭기의 경우 다른 여러 부품과 마찬가지로 이러한 트레이드 오프는 간단한 예/아니요 질문이 아니라 정도와 우선순위에 있어 미묘한 차이가 있습니다.

어떤 응용 분야에서는 해당 상황에서 정말 중요한 한 가지의 우수한 성과를 얻을 수 있다면 일부 파라미터 값이 다소 양호하지 않더라도 큰 지장이 없습니다. 예를 들어 정밀 계측 회로에는 넓은 온도 범위에서 오프셋 드리프트가 낮아야 하는데 이 목표를 달성하기 위해 추가적인 소산은 어느 정도 수용 가능합니다. 여기서 문제는 “가장 중요한 목표를 달성하기 위해 다른 것을 어느 정도까지 포기할 것인가?”입니다. 10%의 오프셋 드리프트 성능 향상을 얻을 수 있지만 그대신 일부 부차적인 성능의 50% 향상을 포기해야 한다면 그럴만한 가치가 있을까요?

또한 비용적 요소가 존재합니다. 거의 모든 응용 분야는 비용에 민감하기 때문에 중요 요소 비용의 한계를 어디까지 둘 것인지가 중요 사안입니다. 몇 센트의 비용을 더 들이는 경우 장치의 잡음이 10% 감소한다면 그럴만한 가치가 있을까요? 이에 대한 답변은 당연히 교과서에는 나와 있지 않습니다.

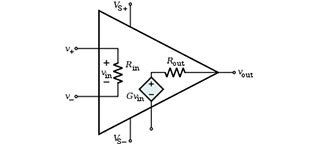

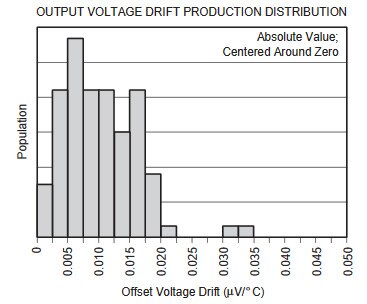

두 개의 "제로 오프셋" 연산 증폭기인 Microchip TechnologyMCP6V51과 Texas InstrumentsOPA735를 예로 들겠습니다. Microchip 장치는 다른 차이점 외에도, ±15V의 초기 최대 오프셋 및 ±36nV/°C의 최대 오프셋 드리프트라는 특징을 지닙니다(그림 1). Texas Instruments 부품은 초기 최대 오프셋이 ±5V로 1/3이지만 최대 오프셋 드리프트는 ±50nV/°C로 약 50%가 더 높습니다(그림 2). 이러한 경우 어떤 부품이 더 나을까요?

그림 1: 주위 온도 대비 입력 오프셋 전압은 정밀 연산 증폭기의 중요 사양입니다. 여기서는 Microchip Technology MCP6V51에 대해 표시되어 있습니다. (이미지 출처: Microchip Technology)

그림 1: 주위 온도 대비 입력 오프셋 전압은 정밀 연산 증폭기의 중요 사양입니다. 여기서는 Microchip Technology MCP6V51에 대해 표시되어 있습니다. (이미지 출처: Microchip Technology)

그림 2: 오프셋 전압 드리프트는 OPA735의 경우 다른 방식으로 나타나지만 nV/°C가 매우 낮습니다. (이미지 출처: Texas Instruments)

그림 2: 오프셋 전압 드리프트는 OPA735의 경우 다른 방식으로 나타나지만 nV/°C가 매우 낮습니다. (이미지 출처: Texas Instruments)

정답은 믿을 수 없을 만큼 간단합니다. 여러 엔지니어링 상황에서처럼 "상황에 따라 다르다"는 것입니다. 이 경우에는 초기 오프셋 값이 드리프트 값보다 얼마나 중요한지에 따라 다르지만, 이는 하나의 특정한 응용 분야에만 해당할 수 있습니다.

원하는 것을 얻기 위해 무엇을 얼마나 포기해야 하는지에 대한 결정은, 여러 요소 및 판단의 신중한 상호작용에 의해 내려지며 이것이 엔지니어링의 핵심 과제입니다. 설계 검토에 관여하는 사람마다 타당한, 다양한 관점을 가지고 있기 때문에 이는 까다로운 결정인 경우가 많습니다.

다양한 응용 분야의 우선순위, 상대적 가중치 및 "무엇을 얻기 위해 무엇을 포기할 것인가"에 관해 무수히 많은 결정을 내릴 수 있습니다. 다행인 점은 이렇게 선택의 폭이 넓다는 것은 (대부분의 경우) 아주 좋은 결과를 찾을 수 있는 기회가 된다는 점입니다. 물론 선택의 폭이 넓으면 복잡할 수 있으며, 설계자가 첫 번째로 보게 되는 장치를 선택해 버리거나 이전에 사용한 적이 있으며 가장 익숙한 공급업체나 장치를 선택해 버릴 가능성도 있습니다.

아이러니하게도, 이미 수많은 연산 증폭기가 있고 계속해서 새로운 제품이 나오고 있는데도, 많은 설계자들은 옳은 결정이든 아니든 결국 자신에게 가장 익숙한 것을 선택합니다.

Have questions or comments? Continue the conversation on TechForum, Digi-Key's online community and technical resource.

Visit TechForum