Options for Powering Your Wireless IoT Device

Electronic Products 제공

2016-04-22

Your wireless IoT device-plan is all set: Sensors are identified, the ultra-low-power processor is selected, and the wireless connectivity format, protocol, and band have been determined (Figure1). One thing remains: ensuring there's enough reliable power for this IoT device to operate unattended, and for the time that the application requires. The IoT device is a power-miser by design, so it shouldn’t be much of an issue to provide the small amount of power needed, right?

Figure 1: The greatly simplified system-level block diagram of a generic IoT design shows its three "external" connections: sensor (or sensors), DC power, and wireless port connection (antenna).

As in most engineering decisions, the answer is not simple. There are many potential options for powering the device, depending on the specifics of the installation: nearby AC line, available DC rail, energy harvesting, or battery. The first two choices require the IoT device remain tethered; the third has more freedom but the IoT device is still constrained by the placement of the harvesting transducer; and the battery-only option offers the greatest flexibility in placement but will need replacement,

AC line: this seems like the easiest option, as it can provide as much power as needed and for as long as needed. The problem is that it will need an AC/DC converter. This AC/DC converter can be a purchased external unit (even a basic "wall wart"); but such converters can be relatively large and costly, and many models are not designed or built for years of reliable operation. Alternatively, a small AC/DC circuit can be built onto the IoT device PC board, but this brings safety and regulatory-approval issues due to the presence of the line voltage, in addition to the cost and size burden.

DC rail: if the IoT is to be used near a DC rail in its associated system, such as in a home appliance, it may be a good option, since a simple on-board DC/DC converter can be small, low-cost, and reliable. Of course, it is important to ensure that this DC rail will be powered and available for when the IoT device needs it, and not be inadvertently shut off by a user or go into a quiescent state where it can’t provide the rail current and voltage when it is actually needed by the IoT load.

Energy harvesting: this is often a very good option, as it can be a headache-free, moderate-cost almost "something-for-nothing" source. The most frequently harvested energy sources are vibration/kinetic (piezo), photovoltaic (solar), and thermal (TEC, TEG, thermopiles, thermocouples). Unfortunately, energy harvesting is often impractical because there is no reliable or consistent source of energy to be scavenged, as many IoT devices are placed in dark, quiet places, and the transducers are inefficient sources of energy that can be scavenged.

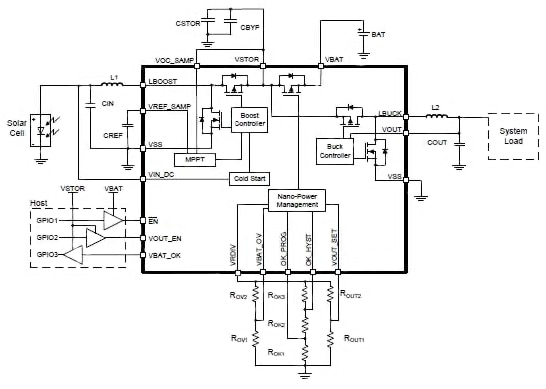

If harvesting is a viable choice, there are self-contained ICs which make it relatively simple and inexpensive to capture sporadic, minute amounts of energy, direct it to a storage element (a supercapacitor is often preferred over a rechargeable battery), and manage its use. For example, the bq25570 boost charger and buck converter from Texas Instruments (Figure 2) is the core of a highly integrated energy-harvesting power supply. It is designed to efficiently extract power generated from a variety of high output-impedance sources ranging from microwatts to milliwatts. The battery-management features ensure that the rechargeable battery or supercapacitor storage element is not overcharged by extracted power, or depleted beyond safe limits by a system load.

Figure 2: The Texas Instruments bq25570 boost charger and buck converter manages power extraction from harvesting sources which can provide microwatts to milliwatts; it also manages the energy-storage component situation for maximum performance and protection.

Battery: At first glance, this may seem like an unattractive option, since batteries eventually need to be replaced. However, it is actually often the most appropriate choice if the battery is properly sized and chosen. For example, a lithium cell with suitable capacity, characteristics, and fabrication can provide years of power, at a low cost, as lithium has the highest energy per unit weight and volume of all commercially available cell chemistries.

Many IoT devices can operate from a single Li-ion cell, which will have a nominal output of 3.6 V when new (depending on specific lithium chemistry) and which can still provide useful energy down to about 2.5 V. If the IoT circuit needs a regulated rail between those extremes, a low-cost, small buck-boost regulator can solve the problem. For example, the LTC3129 synchronous buck-boost DC/DC converter from Linear Technology (Figure 3) delivers up to 15 V at 200 mA. It offers a seamless transition between buck and boost modes, guaranteeing a stable output rail across the entire range of the input voltage. It supports a wide input-voltage range of 2.42 V to 15 V (commensurate with single-cell and multi-cell packs) and a wide output range of 1.4 V to 15.75 V.

Figure 3: the LTC3129 synchronous buck-boost DC/DC converter from Linear Technology seamlessly switches from buck to boost mode so it can maintain a constant output voltage even as output of the source (usually a battery) declines as it is depleted.

Battery parameters critical to IoT success

While battery selection seems like a straightforward process, there are special considerations for IoT applications, since they will often have a long installed life of several years and even decades.

Battery selection begins with the well-known top-tier specifications of nominal output voltage (V) and energy capacity (mA-Hr). Note that batteries with the same nominal number, such as the popular 2016 or 2032 designation, have secondary factors which will affect the decision of which specific battery and vendor to use.

A battery is a reservoir of energy, which it then "gives up" as power. Although the two parameters are intimately related (power is the rate of energy use; energy is the time integral of power use), they are very different quantities.

Matching nominal battery voltage to needed supply rail is relatively easy, but assessing capacity needed may be difficult. Most IoT applications have very low duty cycles, with long periods of deep sleep and almost no current drain (a few μA is commonplace), punctuated by short periods of activity where drain is many orders of magnitude greater (at mA levels). As a result, it is often difficult to accurately quantify what the total energy requirements for the IoT device will be over the needed time period, such as a year.

Beyond nominal voltage and capacity, there are other important considerations when selecting a battery beyond size, type, and source. Among these are operating mode, temperature, and self-discharge rate:

Operating mode: Some batteries are not "stiff supplies" and so cannot deliver the power needed when "pulsed", meaning they are suddenly transitioning from microamp mode to a more-active milliamp mode. This is a called voltage delay or power drop, and can cause erratic operation of the IoT device.

Temperature: both storage and operating temperature are important factors. Industrial IoT devices are often used in hot or cold locations; consumer devices may be in more benign settings but could be used for outside temperature or in security-focused locations. Temperature extremes and excursions affect actual battery capacity and life. Some batteries are both designed and specified for wide-temperature operation, but many are not. Temperature is a potential concern even when the IoT device is not in use, since its batteries may be in transport or storage in adverse conditions, which affects operating life.

Self-discharge rate: this is one of the most challenging factors to consider and characterize with respect to the application life cycle. A standard lithium cell will typically have a self-discharge rate between 2 and 3 percent per year, which compounds quickly and soon yields a viable lifetime of only a few years, even with no external drain. However, there are lithium cells based on similar chemistry but using enhanced design and manufacturing processes, and which have self-discharge of under 0.7 percent/year. The result is an operating life which can be as high as 20 to 40 years.

A look at one high-end lithium cell illustrates the detailed specifications which vendors offer. The Tadiran TL-2450 is a 3.6 V primary (non-rechargeable) lithium-thionyl chloride (Li-SOCl2) disc cell (24 mm diameter, 5.6 mm thick, Figure 4). Its capacity is 0.55 Ah at 0.5 mA, all the way down to 2 V. Maximum recommended continuous current is 5 mA and maximum pulse-current capability is twice that, 10 mA. Operating temperature range is -55⁰C to +85⁰C; along with a 10-year shelf life, the vendor characterizes fast voltage recovery even after long-term storage and/or usage.

Figure 4: The Tadiran TL-2450 is a 3.6 V lithium disc cell designed for at least a 10-year lifetime; it comes with solder pins for "semi-permanent" installation rather than use a cell holder which might corrode over time.

For further demonstration of the IoT fit of this battery, there is detailed performance and long-term data. For example, Figure 5 shows discharge characteristics at 25⁰C and Figure 6 calls out voltage response versus years under a specific set of conditions. Given these specifications, it should be no surprise that the battery comes with pins so it can be soldered into the PC board, rather than using a battery holder.

Figure 5: Vendors of high-end batteries such as Tadiran offer detailed graphs, such as this one which shows output voltage and service hours for a range of supplied currents; note the absence of output-voltage droop.

Figure 6: Battery longevity is clarified with graphs such as this one, which charts pulse-load performance of the Tadiran TL-2450 versus years of service, under specific operating conditions.

Lithium versus alkaline: sometimes difficult, often not

Alkaline batteries are low-cost, widely available, and potentially viable IoT-power choices in some circumstances. They can deliver the needed voltage rating and energy capacity, but should only be used in well-understood scenarios. This includes applications where replacement is not a problem or inconvenience (due to their high self-discharge rate), where they need to work only for a year or two (their crimped seals may leak), or where they will experience only modest temperature swings (their electrolyte is temperature sensitive, unlike lithium batteries which have a non-aqueous electrolyte and so can tolerate greater temperature swings). For most IoT applications a lithium-based battery, although initially more costly, is the preferred choice compared to an alkaline cell or pack of cells with the same nominal voltage and energy capacity.

Summary

The potential weak link in an IoT design is its source of reliable, long-term power. While a nearby AC line or even a DC/DC rail seems to solve the problem, they also tether the IoT device and limit its flexibility in placement. Energy harvesting is a non-tethered "free" alternative but is often hard to implement due to lack of suitable sources providing a viable or consistent amount of energy to be harvested. For these reasons and others, the non-rechargeable battery is often the non-intuitive but best technical choice. Even with a given chemistry and product class, there are critical long-term specifications beyond top-tier obvious ones which must be met, and which distinguish one vendor’s battery model from another’s, even if the voltage and capacity specifications appear to be the identical between products.

For more information about the parts discussed in this article, use the links provided to access product information pages on the DigiKey website.

면책 조항: 이 웹 사이트에서 여러 작성자 및/또는 포럼 참가자가 명시한 의견, 생각 및 견해는 DigiKey의 의견, 생각 및 견해 또는 DigiKey의 공식 정책과 관련이 없습니다.