LED Color Mixing: Basics and Background

Convergence Promotions LLC 제공

2010-12-22

Introduction

This application note explains a few approaches to creating color consistent LED-based illumination products and guides readers in how to work effectively with Cree products to achieve this goal.

LEDs, as with all semiconductor devices, have material and process variation which yields product with corresponding variation in performance. LEDs are binned and packaged to balance the nature of the manufacturing process with the needs of the lighting industry. Lighting-class LED products are driven by the needs of the solid-state-lighting industry, application requirements and industry standards, including color consistency, as well as color and lumen maintenance.

The need for color consistency in LED illumination

There is nothing like a picture to illustrate the need for every illumination technology to deliver consistent color. It is an example of the problem we are trying to solve.

Though this illustration is from an array of HID lamps illuminating the facade of a building, it shows the undesirable results of inconsistent color in manufacture and color maintenance of luminaires as they age.

An increasingly active industrial policy in the United States, European Union and throughout the world, is resulting in a rigorous set of performance requirements for LED lighting applications. For example, the 2010 document “ENERGY STAR® Program Requirements for Integral LED Lamps”2 proposes stringent requirements, significantly above those for CFLs3, the first industrial policy mandated illumination technology. The LED Lamp requirements were preceded by the 2008 document “ENERGY STAR Program Requirements for Solid State Lighting Luminaires4.” In each of these documents, there are requirements in CCT, CRI, lumen and color maintenance for an Energy Star approved LED illumination product, shown in Tables 1 and 2 below.

| Criteria Item | ENERGY STAR Requirements | Reference Standard/Test Method | Sample Size/Specific Requirements | Laboratory Requirements | ||

| Correlated Color Temperature (CCT) and Duv | Lamp must have one of the following designated CCTs (per ANSI C78.377-2008) consistent with the 7-step chromaticity quadrangles and Duv tolerances listed below (see Appendix A for more information). | LM-79-08 ANSI C78-377-2008 | 10 units per model -5 base-up -5 base-down At least 9 out of 10 samples must meet specification |

DOE CALiPER Recognized or NVLAP Accredited for LM-79-08 | ||

| Nominal CCT | Target CCT (K) and tolerance | Target Duv and tolerance | ||||

| 2700 K | 2725 ± 145 | 0.000 ± 0.006 | ||||

| 3000 K | 3045 ± 175 | 0.000 ± 0.006 | ||||

| 3500 K | 3465 ± 245 | 0.000 ± 0.006 | ||||

| 4000 K | 3985 ± 275 | 0.001 ± 0.006 | ||||

| Luminaire Requirements | ||

| Correlated Color Temperature (CCT) | The luminaire must have one of the following designated CCTs and fall within the 7-step chromaticity quadrangles | |

| Nominal CCT(1) | CCT (K) | |

| 2700 K | 2725 ± 145 | |

| 3000 K | 3045 ± 175 | |

| 3500 K | 3465 ± 245 | |

| 4000 K | 3985 ± 275 | |

| 4500 K | 4503 ± 243 | |

| 5000 K | 5028 ± 283 | |

| 5700 K | 5665 ± 355 | |

| 6500 K | 6530 ± 510 | |

These requirements highlight the need to achieve defined, repeatable results with the manufacturing output the LED supplier.

The basic approaches

There are three ways in which a company can work with Cree to procure LEDs to achieve color-consistent lighting products:

- Buy one, or a very small number of bins. The purchase of the same small collection of parts over and over is a reasonable and repeatable strategy, but due to the nature of LED manufacturing this is never the lowest cost way to procure a production supply of LEDs.

- With the release of EasyWhite™ products, beginning in late-2009, Cree has made it possible for its customers to work with LEDs in a way that is similar to original bulb-specification practices, e.g., specifying just CCT and flux. Cree performs color mixing on behalf of its customers in building EasyWhite versions of the XLamp MC-E or MP-L LEDs.

- Traditionally the most cost effective way to work with Cree is to buy full distributions of XLamp LEDs, that is, the full manufacturing output of an LED production run, which includes variety in flux and chromaticity. In order to use full distributions effectively, the customer develops expertise in multi-LED illumination systems and color mixing recipes. Color mixing recipes offer flexible and multiple solutions to create repeatable chromaticity results and can deliver a cost-competitive advantage over the first two approaches.

LED binning

LEDs can be characterized in multiple ways. For color mixing, the two most important dimensions are color and flux. These parameters are collected as part of the LED component manufacturing process and are the basis for the component binning discussed in this document.

Chromaticity bins

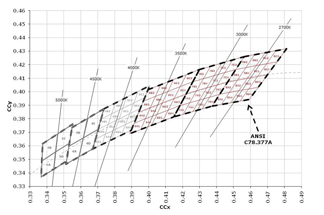

Cree provides industry leading granularity by defining sub-bins within each of the ANSI C78.377 bins for warm, neutral and cool white XLamp products.

Each product family has a binning and labeling document which provides the necessary specification to order Cree LED components.

- Cree® XLamp® XP Family LED Binning and Labeling, CLD-AP22

- Cree® XLamp® MX-6 LED Binning and Labeling, CLD-AP30

- Cree® XLamp® MC-E LED Binning and Labeling, CLD-AP20

Flux bins

Luminous flux is an additive metric just as perceived color is additive. Many types of luminaires are created by laying out arrays of LEDs and summing the flux of the entire array. Cree XLamp LEDs are also characterized by their luminous flux at a nominal current5. An example of this categorization follows:

| Flux Bin | Luminous Flux (Im) | Flux Bin | Luminous Flux (Im) | ||

|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | ||

| K2 | 30.6 | 35.2 | Q3 | 93.9 | 100 |

| K3 | 35.2 | 39.8 | Q4 | 100 | 107 |

| M2 | 39.8 | 45.7 | Q5 | 107 | 114 |

| M3 | 45.7 | 51.7 | R2 | 114 | 122 |

| N2 | 51.7 | 56.8 | R3 | 122 | 130 |

| N3 | 56.8 | 62.0 | R4 | 130 | 139 |

| P2 | 67.2 | 73.9 | S2 | 148 | 156 |

| P3 | 73.9 | 80.6 | S3 | 156 | 164 |

| P4 | 80.6 | 87.4 | S4 | 164 | 172 |

| Q2 | 87.4 | 93.9 | |||

Using colorimetry and binning information in illumination specification

In order to understand why multi-LED color mixing is an important and cost effective manufacturing technique, consider the following hypothetical distribution of LEDs in a large production run. No LED manufacturer can produce uniform color points in their white LEDs; rather they produce batches of LEDs with varying distributions of color, and flux and create inventory based on the results of the production.

Customers who find ways to use a wider collection of color bins can expect to purchase their LEDs at a lower cost than a customer who will only purchase a particular bin.

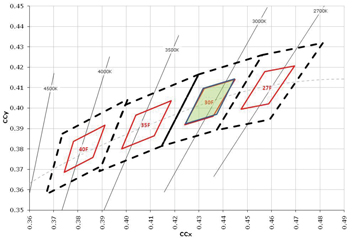

These three approaches are illustrated graphically in the following illustrations.

Three approaches buy single (or few) chromaticity bins

Use Cree EasyWhite parts

Cree EasyWhite LEDs are built using the color mixing techniques described in the next section, offering both excellent color consistency and manufacturing repeatability.

Do color mixing in the LED system

For some multi-LED applications, mixing white LEDs from a variety of bins is a cost effective way to achieve good color quality while minimizing LED costs. In this Illustration we show four LEDs can achieve the same perceived result as if four LEDs from one of the central subbins were used instead.

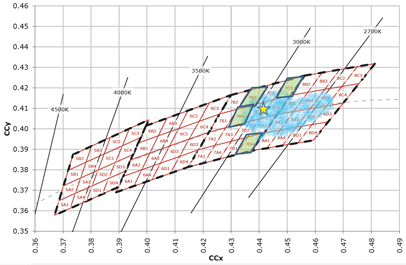

Mathematically the results come because color and flux are additive. LEDs are typically characterized by chromaticity (x, y in the 1931 CIE color space) and flux (Φ =Y).

Tristimulus values, used in color mixing math, can be calculated as follows:

The Combined color is the result of the added tristimulus values:

and

Of course, there are caveats having to do with luminaire design. In order to obtain the benefits of color mixing, the fixture must be far enough away from the observer that the LEDs “blend” together. Alternately there must be a set of secondary optics to mix and homogenize an array of LEDs with slightly different hues.

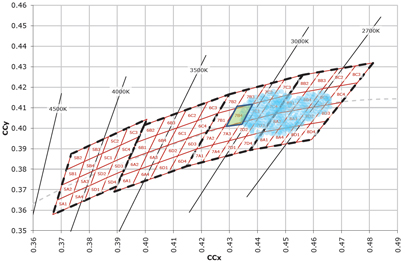

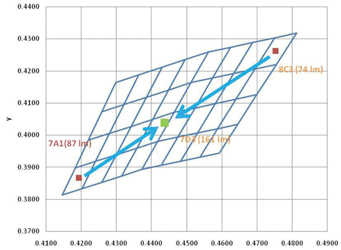

Design example: 2900 K

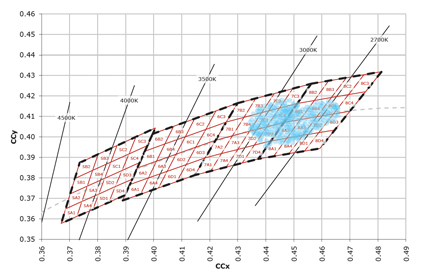

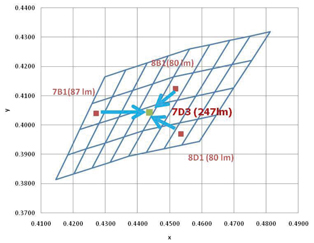

This example is solved in a number of ways. The goal is a 2900 K luminaire and as close to the Black Body Line as possible. A Cree subbin that satisfies this colorimetric requirement is 7D3. Assuming the luminaire is a multi-LED device, there are multiple other ways to satisfy production requirements.

Solution using two bins

Properly mixed, results of these two LEDs deliver light that appears to fall in the 7D3 bin and are illustrated graphically below.

Similar math can be used to achieve color-mixing results with three and four LEDs as well.

Solution using three bins

Solution using four bins

Using color mixing recipes, for every chromaticity target there are multiple ways to utilize the entire production distribution to achieve system results that are color-consistent and cost-effective.

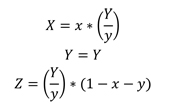

Cree’s color mixing tool, the Binonator

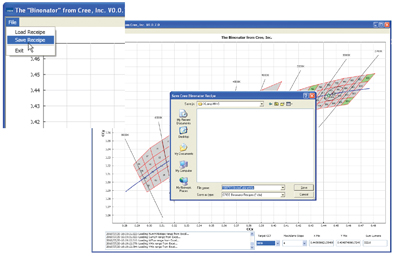

Cree has developed a software tool to automate color and flux math and display resulting output over Cree’s entire defined XLamp color binning space.6

The Binonator is a Microsoft Windows application, and requires a local copy of Microsoft Excel for correct execution. It is available for controlled-access download from the Cree website. In addition to Excel, the binonator requires the Microsoft .NET 4.0 framework for operation. The downloaded file is a self-extracting executable file that installs application and configuration files on a target computer.

Contact your Cree sales representative to get access to Binonator download information.

The tool allows users to:

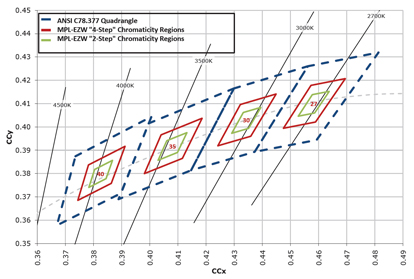

- Specify and visualize an N-step MacAdam ellipse around a series of Correlated Color Temperatures, centered on the Black Body Line.

- Specify a series of LEDs each with associated color and flux bins.

- Calculate the resulting flux and color point.

- Display a graphical result of items one through three above.

- Read and write recipe files to retrieve and store the recipe data.

- The color point of any LED in any particular color bin is the average or center of the bin.

- The flux of the LED is the minimum flux of the selected flux bin.

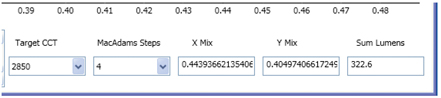

The application is organized into graphical display of the unit (x,y) color space, a status message box (lower left-hand side), settings for Target CCT and number of MacAdam Steps (bottom of display, mid-section), and the calculated results (lower right side).

Select any chromaticity bin by “right-clicking” in the parallelogram that defines the bin. This will cause a menu to display which has a pair of input values for the selected bin. The drop down menu to the left is the union of all flux XLamp flux bins associated with a particular color bin. The cell on the right accepts an integer number of LEDs associated with the bin. Left click the “Submit” button to select the values. The resulting bin will change color to denote the non-zero values associated with the bin. In figure 12, above, we recreate the manual results of Figure 11.

The resultant chromaticity point is displayed, and the coordinates and flux results are presented in the bottom right hand corner of the display.

Controls for the display of a target CCT and a N-step MacAdam Ellipse are at the bottom of the display. These are a pair of drop down menus to display a target Correlated Color Temperature and N-step MacAdam ellipse centered about the CCT. These items allow for the graphical display of a target constraint for the color mixing exercise.

Finally, color mixing recipes can be saved to a file and read in to the binonator by clicking on the File dialog.

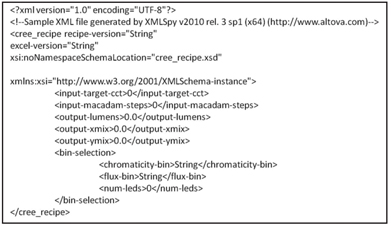

The collection of LEDs and their chromaticity and flux bins are called a recipe and are stored in a file with the .cbr (Cree binonator recipe) extension. The Binonator allows for recipes to be written to a file for storage and subsequent retrieval. The files are organized in an XML-based schema.

Conclusions

Mixing is an effective technique to achieve consistent, repeatable multi- LED luminaires. With the Binonator mixing software, Cree has provided a tool to assist our customers in creating chromaticity bin mixing recipes for their LED illumination products.

For any desired color point in the ANSI bin color space, there are large numbers of solutions to utilize Cree’s full distribution, achieve the best possible LED unit costs and deliver consistent color point results.

Bulb and luminaire designers will want to take care to develop appropriate methods to obscure the color variations across an array of LEDs. In the case of cool white LEDs in very bright applications, such as streetlights, almost no special consideration for mixing optics is required. The distance of the source from the viewers combined with the human visual system’s reduced sensitivity to blue spectrum makes for an easy mixing result. Arrays of warm-white LEDs require more care to make sure an appropriate level of in-luminaire mixing occurs so as to obscure the contributions of each LED.

- Picture: Taken from “The Roof,” The Wit Hotel, Chicago (Courtesy of Osram).

- http://www.energystar.gov/ia/partners/manuf_res/downloads/IntegralLampsFINAL.pdf.

- See http://www.energystar.gov/ia/partners/prod_development/revisions/downloads/cfls/CriteriaCFLs_V4.pdf.

- http://www.energystar.gov/ia/partners/product_specs/program_reqs/SSL_prog_req_V1.1.pdf.

- Most often 350 mA.

- Contact your Cree sales representative to obtain a copy of the Binonator.

면책 조항: 이 웹 사이트에서 여러 작성자 및/또는 포럼 참가자가 명시한 의견, 생각 및 견해는 DigiKey의 의견, 생각 및 견해 또는 DigiKey의 공식 정책과 관련이 없습니다.